Features

- For spices, Herbs, Ingredients, seeds, plants.

- Semi Continuous Process.

- Uniform treatment through gentle movement of product.

- Pre-Heating and Sterilization of product in same vessel, followed by cooling

- Every single particle is treated at same parameter.

- Natural treatment, No chemical Residual contamination.

- Easy to Operate,

- Short time process.

- Labor saving.

- Low running cost.

- Safety Devices

- Computerized controls with data saver.

- Repeat accuracy.

- Micro load reduction up to 5 logs.

- Disinfection, Pasteurization and Sterilization.

- Capacity/Batch: 250 kg, 500 Kg, 750 Kg

- 1000 Kg (0.5 Bulk Density)

- Process Time about 30 minutes.

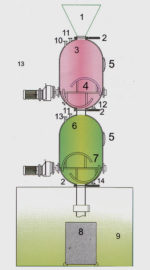

Sterilizer Flow Diagram

1. Hopper with load cell

2. Valve

3. Pre-Heating & Sterilize

4. Stirrer

5. Manhole

6. Product Cooler (Vacuum)

7. Stirrer

8. Sterile Product Container

9. Clean Room

10.Steam In

11.Vacuum Line

12.Condensate

13.Water Outlet

14.Chill Water Supply